|

| |

BDT series Biodiesel Processors |

|

| Biodiesel processing units of Biodiesel Technologies, Kolkata, India produce ASTM D6751-compliant biodiesel from any vegetable oil or animal fats with an Acid Value of 5% or less. Production rates range from 5000 Lts. To 5,00,000 Lts.per day. This production rate includes down time for regular maintenance and upkeeps well as personnel shift changes throughout the day. |

| |

BDT-Series Biodiesel Processing Unit Highlights: |

|

|

Guaranteed to produce ASTM D6751-compliant biodiesel |

|

Continuous Flow/ Modular Batch Transesterifiers, available |

|

Waterless wash-zero water in - zero waste water out |

|

Skid mounted, versatile and expandable |

|

Includes complete Installation, start up, & transitional assistance |

|

All units include a 5-day training curriculum and proficiency testing with a certified technician for up to FIVE of your employees |

| |

|

Turn-key custom installation with complete build-out available |

| |

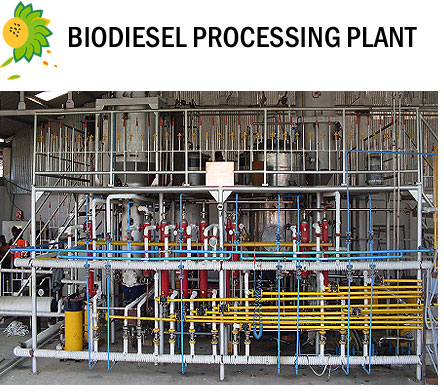

30 MTPD Multifeedstock Biodiesel Processing Plant operating on a Commercial Scale |

|

| |

| Our Product Line - Multifeedstock Biodiesel Processing Plants BDT Series |

| |

TECHNOLOGY |

|

Building a greener future today starts by accessing the technology of tomorrow.

At Biodiesel Technologies, we work hard to provide the best in class technology through continuous process of improvement and innovation in our processing plants.

Our highly praised BDT-series processing units are the harvest of the effort. By looking outside the realm of contemporary biodiesel processing, Biodiesel Technologies has integrated scientific solutions from industries all over the world, in production quality, system automation, chemistry, filtration, and efficiency. Biodiesel Technologies benchmark leadership continues to provide the Biodiesel industry with breakthrough advantages. The Biodiesel Technologies Processing Advantage produces the highest quality biodiesel, significantly exceeding all minimum standards for quality established by ASTM D6751 specifications. The fact that all our BDT-series processing units are modular and have extremely low operating cost, is further example of Biodiesel Technologies, Kolkata, India’s commitment to our customer’s needs.

Our company was founded upon the ideal of creating a greener world. Biodiesel Technologies’ process removes all water content in the first stage of processing and never reintroduces water in the subsequent stages, thus completely eliminating the risk of adding waste or contaminated water to our already taxed environment. Our pledge to the environment and the biodiesel industry is to create clean systems that have zero waste stream, now and in the future.

Biodiesel Technologies builds in versatility for an ever changing world. This advantage allows our customers to select feedstock based on availability and price advantages.

Our BDT-series processors are built to be operated by an operator and one assistant. Biodiesel Technologies, Kolkata, India also offers custom automation systems that can be monitored from a single computer. Biodiesel Technologies, Kolkata, India is committed to innovation, quality, and customer satisfaction. Let Biodiesel Technologies help you to start building your biodiesel processing facility of the future, today! |

| |

| Feature |

Description |

Competitive Edge |

|

| Chemical Adsorbent made by World's best chemical solutions group. |

Chemical Adsorbent allows a waterless wash process with a zero toxic waste stream. Fuel produced is ultra dry and has a longer shelf life due to less oxidation and no exposure to water. |

Reduces oxidation from water contamination.

Eliminates the need for water supply and Haz Mat disposal permits.

Eliminates wastewater treatment system, thus reducing initial cost and reoccurring plant power requirements.

Avoids EPA permitting issues. |

|

| Premixed Liquid Methylate available in the market |

Catalyst and Methanol premixed together. |

Does not require mixing methanol with caustic and provides better safety for personnel. |

|

| Modular System |

Skid mounted modular design |

Skid mounted modular design |

|

| Scalable System |

Expandable capability up to the limitations of the model |

Can easily scale your processing capacity to meet your requirements. |

|

| State of the Art Automation |

Touch screen controls

Remote tank level monitoring |

Fully automated system with computer interface. |

|

| Large Range of Processor Sizes |

5000 Ltrs/Day to 3,00,000 Ltrs/Day. |

Ability to choose exactly the right size system for your specific requirements.

Modular design allows for capacity up-grades. |

|

| |

BDT MINI series |

|

| To redefine the technology of Biodiesel Production and to offer this to the Indian Home Brewers and small producers, we have brought in the following Mini series of Biodiesel Processors which are capable of Producing Biodiesel from the following feed stock available in the Indian Subcontinent: |

| |

|

Karanj oil |

|

Madhucha oil |

|

Neem oil |

|

Jatropha oil |

|

Waste Vegetable oil |

|

Rubber seed oil |

|

Animal Tallows |

|

Acid Oils ( RiceBran, Palm etc) |

| |

These series of Biodiesel Processors are named BDT MINI SERIES

The Sizes of the Processing plants are as follows: |

| |

|

1000 Lts per day - BDTMS 1K |

|

2000 Lts per day - BDTMS 2K |

|

3000 Lts per day - BDTMS 3K |

| |

| These systems are very easy to operate and can be mounted on Tractor trailers as well for field production. |